Our Story

1907–1930: Foundations and the Rise of Spruce Falls

Early Beginnings (1907–1916)

At the turn of the 20th century, the dense northern forests of Ontario remained largely untouched. That changed in 1907, when the community of MacPherson (later renamed Kapuskasing) was established to support the growing needs of railway construction. In 1914, the area saw its first wave of settlers — prisoners of war tasked with clearing land to pave the way for permanent communities and future industries.

By 1916, signs of industrial promise began to appear. Timber cruising operations, led by pioneers like Mundy and Stewart, mapped out the vast resources hidden in the boreal landscape. Their efforts secured the initial timber rights that would soon attract major players to the region.

Birth of Spruce Falls (1917–1922)

In the years that followed, the timber rights first acquired were transferred to a new entity: Spruce Falls. The company quickly moved to formalize its ambitions, and in 1920, the Spruce Falls Company was officially incorporated. It wasn’t long before the first sulphite pulp rolled off production lines in 1922, marking a major milestone not just for the company and its 500 employees, but for the entire Kapuskasing area. The town’s future was no longer tied just to the railway — the pulp and paper industry had arrived.

Industrial Growth and Partnerships (1926–1930)

The momentum only grew stronger. In 1926, Spruce Falls Power and Paper Company emerged, bolstered by major investments from two giants: Kimberly-Clark and The New York Times. With this powerful backing, the company expanded its timber concessions and established a dedicated Woodlands Department to oversee forest operations.

By 1928, Spruce Falls had achieved another first: exporting newsprint from Kapuskasing to markets far beyond Northern Ontario. The once-remote settlement was becoming a crucial link in the North American paper supply chain. By this time, employment had grown to 1,000 workers, newsprint production had reached 590 metric tons per day, and the Mill was operating five days per week. Timber cruising and operational expansion continued through 1930, laying a sturdy foundation for even bigger developments to come.

1931–1955: Challenges, War Efforts, and Mechanization

Surviving the Depression (1931–1938)

Like much of the world, Spruce Falls struggled through the Great Depression. From 1932 to 1935, operations were reduced to just two to three days a week. However, by 1937, the company had begun to invest in new equipment, preparing itself for better times ahead.

World War II and Workforce Changes (1939–1949)

As World War II unfolded, Spruce Falls found itself adapting once again. The former POW camps were reactivated, and Japanese Canadians displaced from British Columbia were brought in to fill labor shortages at the Woodlands camps. During this period of upheaval, Spruce Falls pushed forward with improvements. The Sulphite Mill’s circulating and packer system was installed, and a second sulphite dryer was added soon after to boost capacity. In 1942, the Evening Star Newspaper Company acquired a minority interest in Spruce Falls, strengthening the company’s financial footing. A few years later, reforestation efforts advanced with the establishment of the Moonbeam Forest Nursery, and aerial photography was completed to better map and manage the forest limits. By the end of the decade, Spruce Falls had emerged as a leader in forestry innovation, setting new standards for sustainable operations.

Early Mechanization and Fire Management (1950–1955)

The 1950s were a transformative decade for Spruce Falls, filled with advancements and milestones. In 1950, power saws replaced the traditional buck saws, boosting productivity and easing the physical toll on workers. By 1953, the Moonbeam Nursery’s first transplants took root, and a comprehensive forest inventory was completed, paving the way for the future.

Kapuskasing, too, was growing. In 1951, Prince Philip and Princess Elizabeth visited the mill, witnessing Spruce Falls’ significance to the town. By then, the population had reached 5,000, with Spruce Falls employing 1,500 people and producing 750 tons of newsprint daily—half for The Times, the rest for other customers. The company’s cutting rights had expanded to 6,360 square miles, signaling even more growth ahead.

However, nature still posed challenges. In 1955, the region experienced an unusually high forest fire hazard that lasted through most of the summer, reminding everyone that even in an era of mechanization, the natural world remained unpredictable. The 1950s laid the groundwork for a new era, where innovation and progress shaped the future of forestry.

1956–1975: Expansion, Major Modernizations, and Rising Output

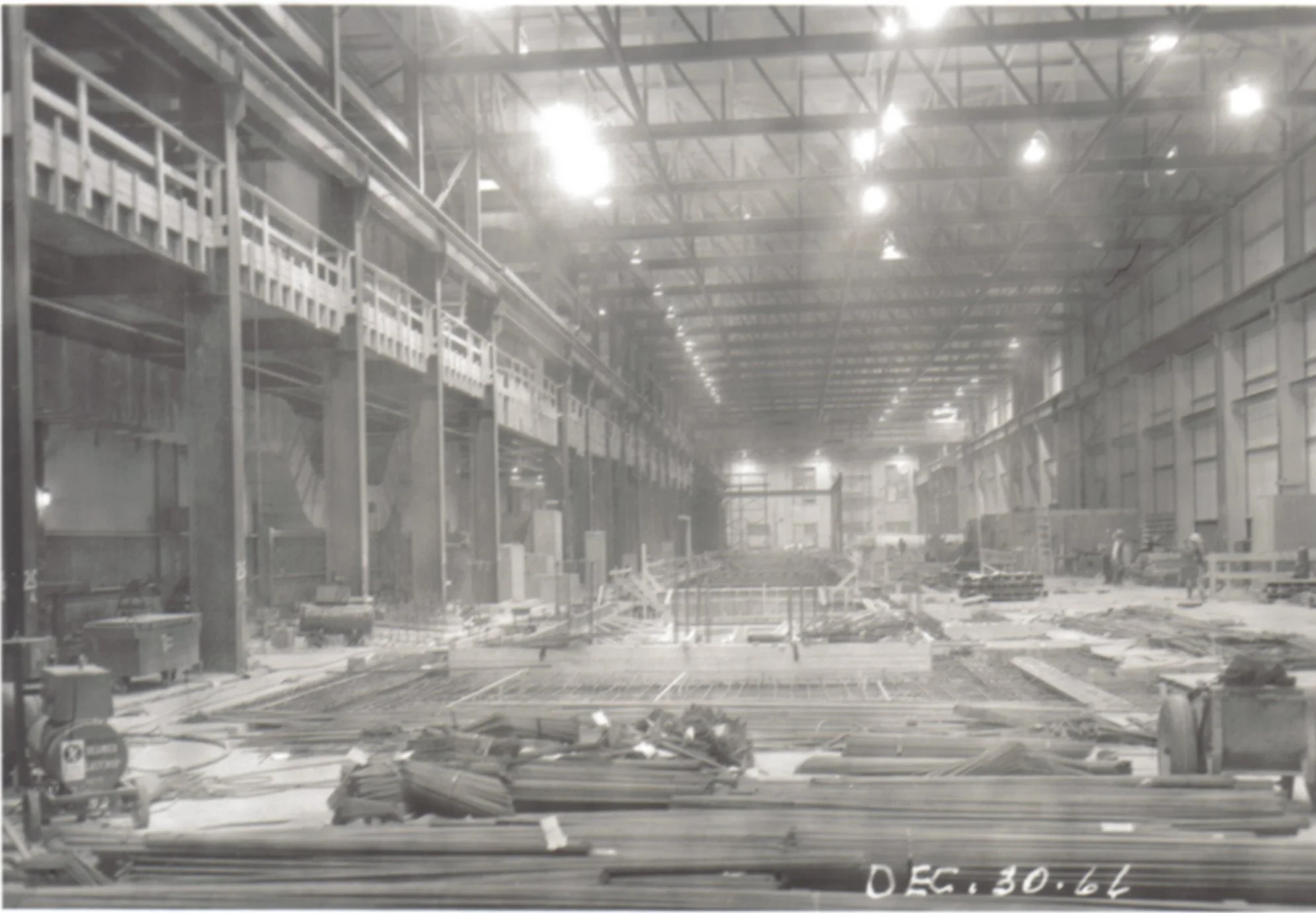

Major Mill Upgrades (1956–1964)

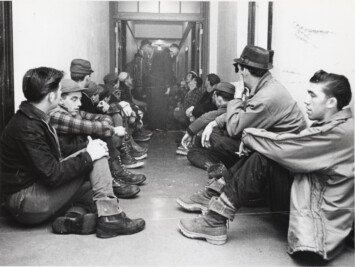

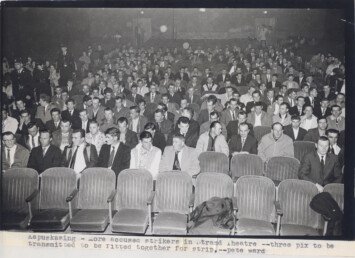

The late 1950s and early 1960s were transformative years for Spruce Falls. The mill, always adapting to the times, took on a massive overhaul. Key paper machines were rebuilt, old power boilers were replaced, and sections of the sulphite dryer were completely revamped. A new sulphite bleachery was installed, helping elevate both pulp quality and output. As the operations grew, the second sulphite dryer was retired, and a steam recovery boiler was introduced to meet rising production needs. But not all was smooth sailing. In 1963, a major strike halted operations for nearly a month, testing the resilience of both workers and management. Tragically, fatalities occurred during the strike, underscoring the tensions and risks of the moment. Yet, this setback didn't slow the company’s forward momentum. By the mid-1960s, the Magnefite Mill began its operations, and in the forests, wheeled skidders replaced horses — a symbolic shift toward a more mechanized future.

Modern Logging and Transportation (1965–1971)

By the second half of the 1960s, Spruce Falls was fully embracing the future. The company pioneered new methods in logging: tree-length logging replaced the traditional shorter cuts, dramatically reducing waste and handling time. The No. 5 paper machine began operating in 1967, pushing production even further, while mobile slashers became a regular part of the logging process. Alongside these innovations, environmental responsibility took center stage with the installation of a clarifier, improving the treatment of mill effluent. Transportation improvements were also critical, and the completion of the bridge over the Kapuskasing River eased the flow of timber and workers across the expanding company territory. These were years of growth, not just in capacity, but in the company's overall approach to operations.

Innovations in Forestry and Mill Capacity (1972–1975)

The early 1970s were a mix of consolidation and bold moves for Spruce Falls. In a strategic shift, the company sold the Moonbeam Nursery to the Ministry of Natural Resources, ensuring its ongoing role in reforestation efforts. A new sawmill came became operational, ramping up lumber production, while changes in ownership saw the Evening Star Newspaper Company sell its minority stake. But the real story was in the forests. New equipment, like upgraded skidder tires, hydraulic rake boats, and drop deck trailers, made logging operations more efficient than ever. By the mid-1970s, Spruce Falls reached a milestone — producing 1,000 tons of newsprint daily and employing 1,500 people. As the company continued expanding, the move of the head office from Toronto to Kapuskasing was a symbolic gesture, cementing the company’s deep ties to the northern community. It was a turning point that marked the beginning of a new era in growth, production, and innovation.

1976–1991: Continuous Upgrades and the Shift to Employee Ownership

Mill and Woodlands Modernization (1976–1980)

The late 1970s marked another turning point for Spruce Falls. In 1976, the company installed a new chip handling system to prepare for the future Thermomechanical Pulp (TMP) mill, while also expanding its capabilities with the purchase of a helicopter. Changes moved quickly. Paper machine speeds were increased, the Smoky Line Railway was removed and converted into a gravel road, and major operations — including the sulphite dryer, bleachery, and chip mill — were shut down in 1978 to make way for a $70-million, five-year modernization program. Nature tested the company's resilience again in 1979, when flood conditions caused the failure of the main holding works, sweeping away 25,000 cords of wood downstream. Still, by 1980, computerized moisture and weight control systems were being installed across the mill, and a new Forest Management Agreement was signed with the Province of Ontario — securing the company's long-term access to resources.

Harvesting Mechanization and Process Innovations (1981–1988)

The 1980s ushered in a wave of automation and mechanization across both mill and Woodlands operations. New computerized systems were installed on paper machines to control basis weight and moisture more precisely, while a second line for the TMP mill and a second clarifier began operating. As sulphite operations wound down, the Magnefite Mill was refurbished and successfully restarted, signaling a full pivot toward newer processes. In the woods, harvesting operations underwent a complete overhaul: feller bunchers, stroke delimbers, and high-flotation skidder tires were introduced, followed by forwarders that replaced traditional skidders. Camps 80A, 80B, 86, 115, and 95 were mechanized or closed as live-in forestry camps became a thing of the past. Investments continued within the mill, too, with the installation of Top Flyte top-wire units and new calender stacks to boost production quality. Even amid a short strike in 1988, modernization continued at a steady pace.

Major Transition to Employee Ownership (1989–1991)

By the end of the 1980s, Spruce Falls was a very different company than it had been just a decade before. The 100-millionth tree was planted across company limits, forwarders were fully integrated into harvesting operations, and a new central garage was built to replace older scattered depots. But the biggest change came in 1991, when ownership itself shifted hands. Spruce Falls Power and Paper Company was officially acquired by its employees, Tembec, and the community of Kapuskasing, forming Spruce Falls Inc. — marking a bold new era of local stewardship, resilience, and pride.

1992–2024 – New Production Lines, Ownership Changes, and Industry Shifts

Expansion and Facility Upgrades (1992–1996)

The early 1990s were a time of rapid development at Spruce Falls. TMP Line 3 was launched, bringing a fresh boost to pulp production, while a new De-Inking Plant (DIP) also came online that same year. Upgrades to the No. 3, No. 4, and No. 5 paper machines continued steadily, modernizing core operations. Yet, this era of growth was also marked by difficult transitions. The Magnefite Mill was permanently shut down, followed shortly by the closure of the Groundwood and Woodroom operations, ending the era of river drives that had once defined the region’s forestry practices.

Despite these closures, new opportunities emerged. The sawmill reopened, secondary wastewater treatment began, and the second phase of the DIP Plant started operations. The No. 1 paper machine was also restarted, symbolizing renewed momentum. By the mid-1990s, TMP Line 4 was launched, replacing the aging Lines 1 and 2 and setting a new standard for efficiency in pulp production.

Ownership Changes and Mill Challenges (2009–2024)

The next decade brought fresh challenges. In 2009, the mill shut down temporarily, and over 500 employees were laid off. In 2017, Tembec was acquired by Rayonier Advanced Materials, shifting the ownership structure once again. Four years later, in 2021, GreenFirst Forest Products took over the mill operations in Kapuskasing. And most recently, in 2024, GreenFirst restructured, leading to the formation of a new standalone company: Kap Paper — the latest chapter in over a century of forestry and papermaking in Northern Ontario.